Some machines in my shop, Also some small jobs that I have done

Sharp first mill with EMX Proto Trak control (CNC)--- A 5c speed ex 360 with 4” chuck with adjustable tailstock, Semi -universal dividing head with spline cutters and arbors, also a Boring head for perfectly straight holes.

Sharp surface grinder with a 6”x14” Walker Cermax table Angle plates, Mag Blocks and flat, grinding wheels, precision angle and radius dresser, angle and flat Vice, also 5c collet indexer.

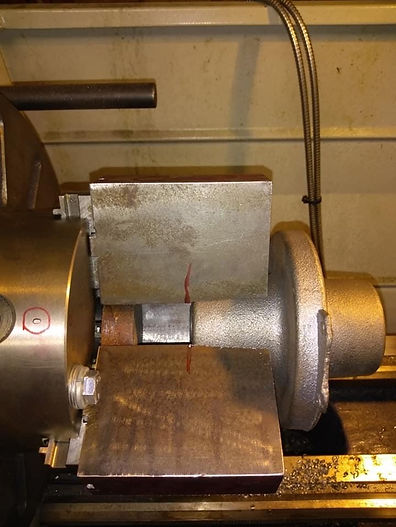

Bolton Tools lathe BT1440G with 2” receiver hole on a 14”x40” gunsmithing lathe. Turning and threading with Carbide, ceramic, also high-speed tooling to do wide variety of projects.

Grizzly model # 9969 radial arm drilling and tapping press--- with a reach of 24” on a 360 degree turn and max height of 60”

4.5” metal cutting vertical, horizontal band saw. Also have a 4” porta band saw.

Central 20 Ton press--- with a Pittsburgh air/hydraulic bottle jack for easy quick movement for broaching Internal keys.

Central Pneumatic 40 lb. capacity floor bead blaster cabinet.

Overhead vacuum system--- for bead blaster, surface grinder and belt sanding in the grinding area.

60 Gal 5Hp 165 pls oil lubricated air compressor for constant Air flow for air tooling needs.

Drills, reamers, cutters, indexable cutters, cuter holders for spline cutters, splitter saw and verses other tooling. Wide variety of measuring tools, indicating parts with indicators, gage blocks, mikes, calipers and height gage.

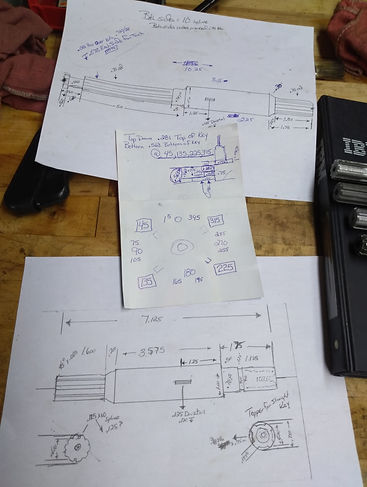

SPLINE SHAFT

AFK PROJECT

I had gotten a job through AFK Corp. in Ripon WI. which is a foundry that needed some jaws made to hold parts that they can have there CNC grinder do. First part of the start of the project is to mount their chuck to my face plate to run true so I can make jaws for their chuck to hold the parts they want to run thru the machine. After mounting the chuck to the face plate I made them 2 sets of 3 jaws to set up and get started on. First set was machine the jaws to fit the chuck and receive the jaws that fit the chuck but 4 inches higher. Second set was to hold the casting you see in the picture which has a draft of 3 degrees to have the sand mold slid away from the sand mold to have the metal poured into to form the casting that has a parting line they want ground evenly all around on the CNC.

Now that they have the 2 sets of jaws to practice with we have to wait for some plates to come in that they ordered to mount to the CNC that we have to mount the chuck to also with the plates they want to mount different castings.

So this is just a start of many things that they want to run into the CNC machine, and a great chance to make fixtures for this company.

I am only a phone call away